description

Lafarge™ Natural Hydraulic Lime (NHL) is made by burning a pure naturally occurring hydraulic limestone from their quarries in the French Alps, an area renowned for the quality of their stone. LaFarge NHL does not contain any Portland cement or additives of any kind.

LaFarge NHL contains over 42% free lime, aiding in the workability and breathability of mortars and plasters made with it.

Natural Hydraulic Limes are commonly used as a replacement mortar in structures originally built of hot and non-hydraulic lime mortars due to their resilience to harsh conditions and normal weathering. They also make ideal mortars and plasters for historic preservation and green building.

Properties

- 100% Natural Product

- Sets Under Water

- Improves Workability of Mortar and Plaster

- Reduces Cracking/Improves "Flexibility" of Masonry Assemblies

- Gradual Strength Gain

- High Moisture Permeability

- Low Modulus of Elasticity

- Good Freeze/Thaw Resistance

- Proven Track Record

technical data

Uses

- Mortar

- Limewash

- Plaster

- Stucco

- Injection Grout

- Stone Consolidation

- Specialty Uses

Color

The raw limestone used to produce LaFarge NHL is of the highest quality, producing a lime with a whiteness index of over 92. This produces a binder which more closely matches aggregate color than any other hydraulic lime sold in North America. LaFarge NHL can be tinted with earth pigments.

Packaging

Lafarge™ Natural Hydraulic Lime is available in the following sizes:

- 55 lb bags

grades

Natural Hydraulic Lime is available in three classifications: NHL2, NHL3.5 and NHL5. These terms refer to each grade's degree of hydraulicity, that is, their ability to set under water without exposure to air. For most applications, the properties of NHL3.5 are ideal.

projects

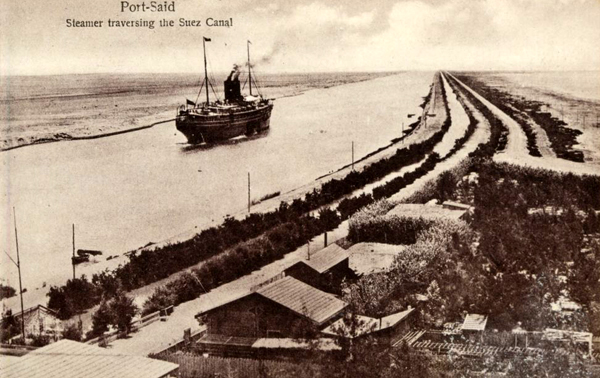

1864 . Suez Canal

Lafarge won the “contract of the century” in Egypt! 200,000 tons of hydraulic lime, delivered in wooden barrels, were needed to build the piers of the Suez canal. Although its production capacity was limited to just 20 kilns, which produced 50,000 tons per year, Lafarge rose to the challenge. The canal opened on November 17th, 1869, and connects the Mediterranean Sea to the Red Sea.

Contact

info@freedomcement.com

(866) 254-7277

Mon - Sat: 9:00 a.m. - 5 p.m. (EST)